|

|

Post by Mastercaster on Apr 20, 2012 12:42:10 GMT -8

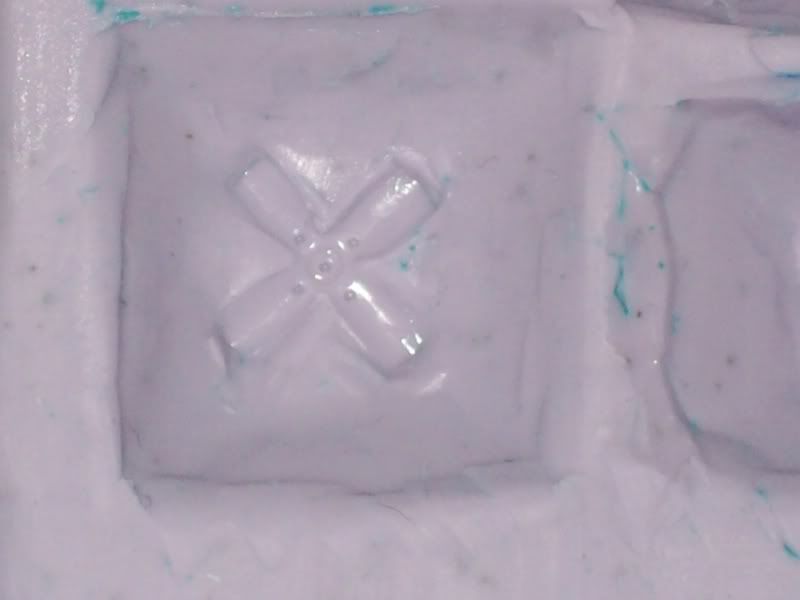

Small parts generally stick to the clay. I really don't like this to happen. When it does I make certain no blue clay residue is on or near the part and I spray a shot of mold release in the socket where the part fits. Why do I do this? It acts a a lubricant to help seat the part where it is supposed to be. A ghost layer of silicone can also form under the part. You won't even know it for awhile. After making several sets of parts the heat built up from the resin curing will eventually loosen this hair thin layer and you can pull it out. OR, it may not happen at all. This phenomenon typically happens on the lower portion of body molds and is usually obvious when you make bodies from a new mold. DO NOT attempt to remove a part from your mold if it did not stick to the clay and got pulled out by it. One time consuming way I thought of to overcome the clay pulling a part out with it is to make thinner layers of clay that would be stacked up to make a 3/8 inch thickness and then I might be able to pull the thin layers away one by one. I do have a 1/16" deep groove on my board I use to shape clay strips. I will have the molds done in time to get Scotty's parts back to him.  Here are the molds finished and vents cut in the top half. The fan blade came out when I removed the clay as above. When I parted the two halves there was thin layer of silicone I mentioned covering the fan blade and yet it picked up the detail of the hub and four bolts like normal.  See? |

|