|

|

Post by Mastercaster on Jul 17, 2015 0:45:22 GMT -8

Here is the start of plunger mold number three. A recipe designed by the good folks at Reynolds Advanced Materials of Tempe, Arizona. I will start with this beautifully painted master plunger by Raoul Coulombe, our French master maker and art impressionist. |

|

|

|

Post by Mastercaster on Jul 18, 2015 13:10:28 GMT -8

|

|

|

|

Post by Mastercaster on Jul 19, 2015 6:13:05 GMT -8

Now I have the inside part of the mold made.  In order to keep the project centered I drilled a hole in this board 1 1/4 inches in diameter. The new silicone inner core fits loosely in the plunger master so it needs to be all held in place.  This chrome pipe fits perfectly in the hole in the board.  So far so good, my plan is working. I just need to shorten the chrome pipe.  I shortened the pipe and put silicone sealant on the parts to help keep it stable for the next step. |

|

|

|

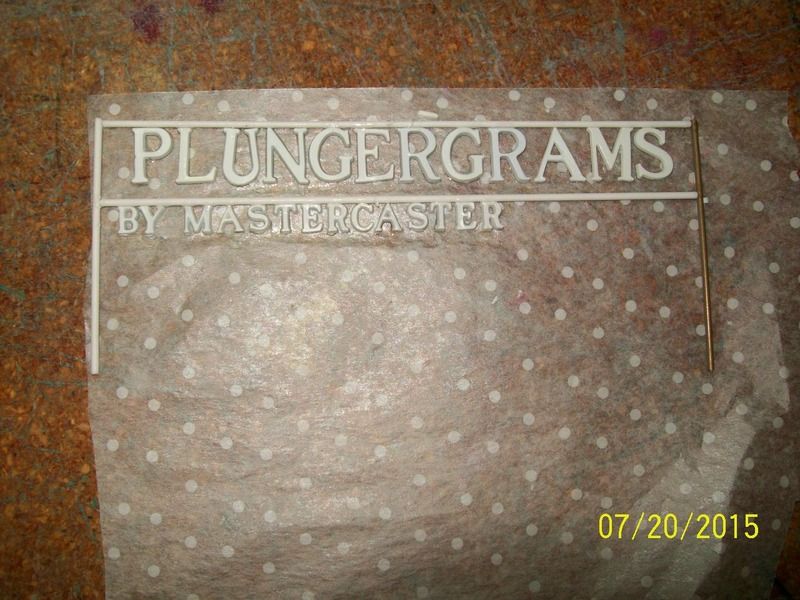

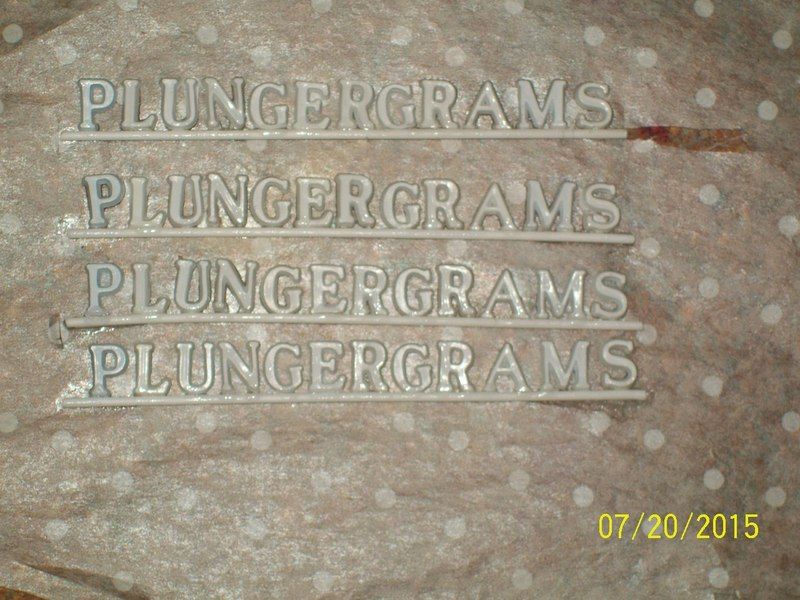

Post by Mastercaster on Jul 20, 2015 20:45:46 GMT -8

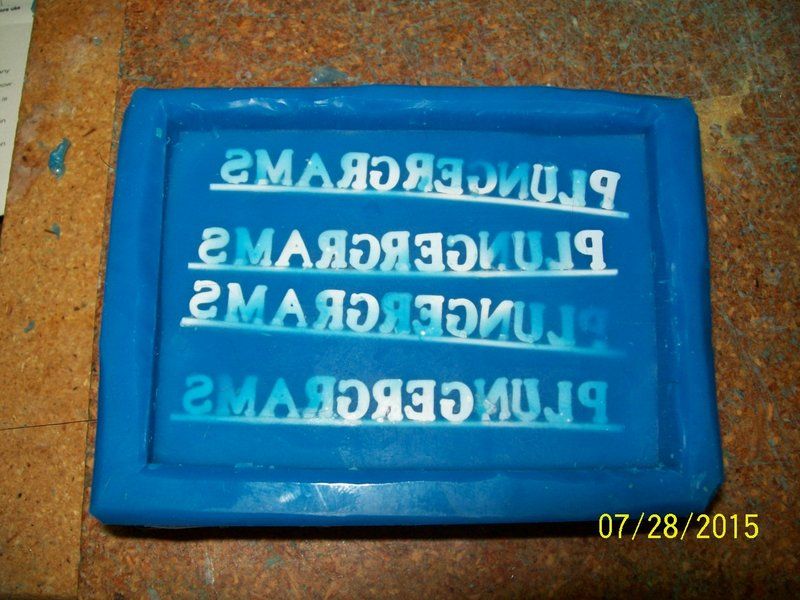

I dug through my boxes of letters I took from the old hospital that ASU has as a community center and made this sign for my plunger. I will attempt to cast it in a rubbery type of eurothane and cast it in the wall of the plunger. If this works I hope to be a famous artist like Andy Warhol. One day long after I'm dead my plungers will be worth billions of dollars. LOL  I decided to make four small ones while as was at it. These will be placed randomly going in different directions and different colors. |

|

|

|

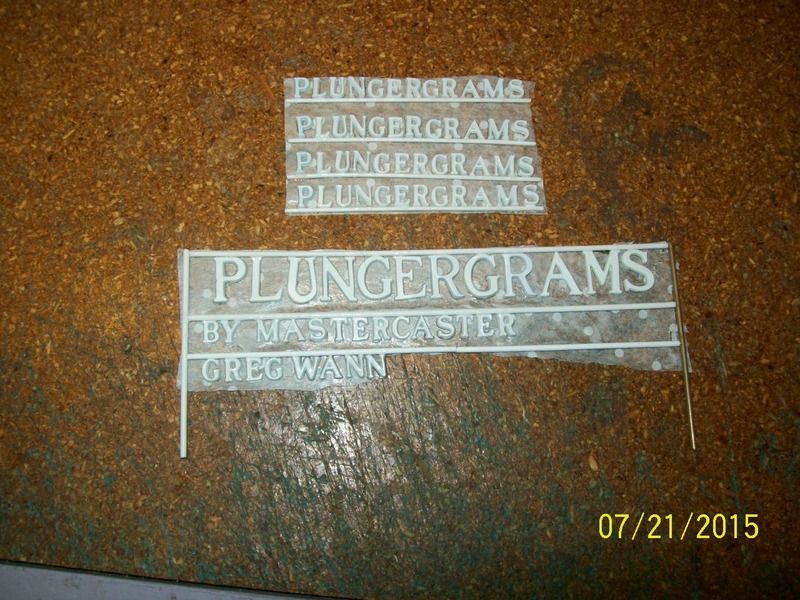

Post by Mastercaster on Jul 21, 2015 8:04:16 GMT -8

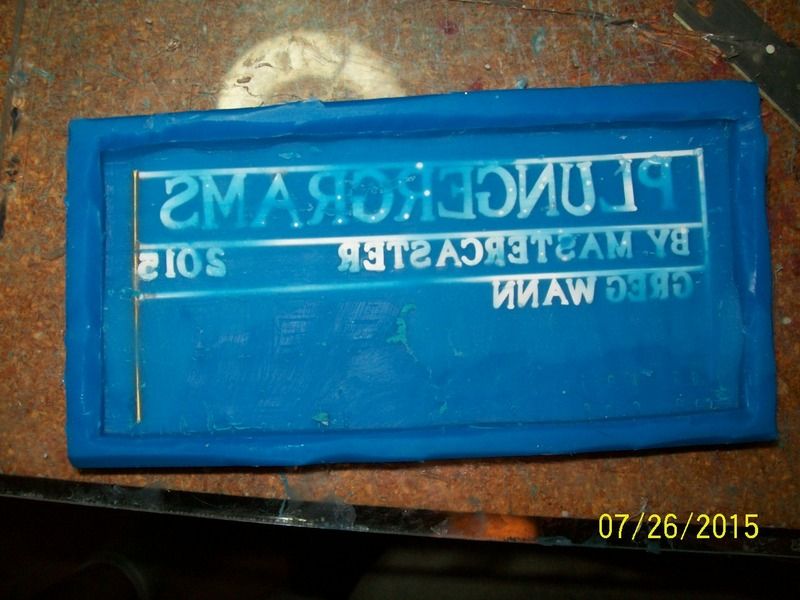

After all this work I might as well add my own real name. This might be an important legal thing to do. I did buy Plungergrams.com to fend off theft. |

|

|

|

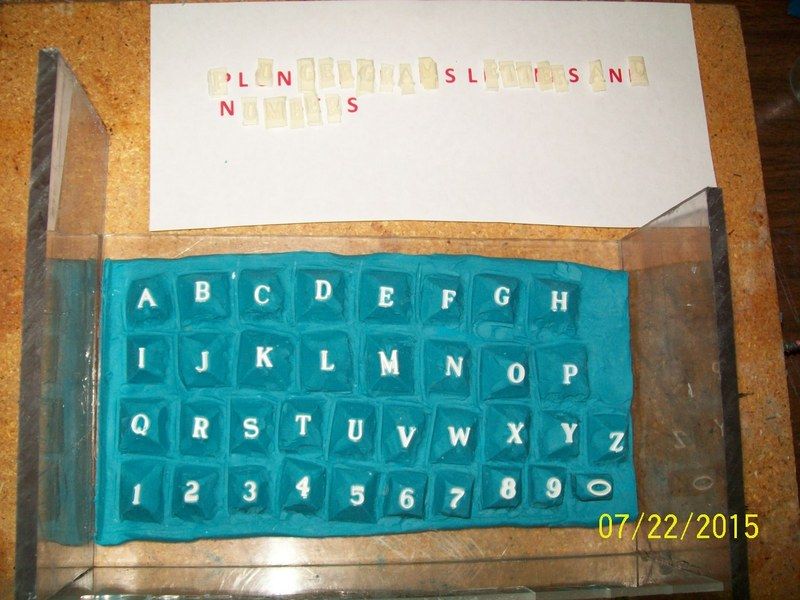

Post by Mastercaster on Jul 22, 2015 15:00:38 GMT -8

Here is a brand new set of letters for the mold. These have no backing. They will be made out of a flexible urethane rubber. |

|

|

|

Post by Mastercaster on Jul 25, 2015 10:25:22 GMT -8

Here is the finished mold. I am happy that this molds fits in the large pot that I make bodies in. |

|

|

|

Post by Mastercaster on Jul 25, 2015 21:43:29 GMT -8

|

|

|

|

Post by Mastercaster on Jul 26, 2015 17:25:05 GMT -8

Now I made this ring. This mold will make a ring that will go inside of each plunger I make......well, that's the plan anyway. |

|

|

|

Post by Mastercaster on Jul 28, 2015 10:31:36 GMT -8

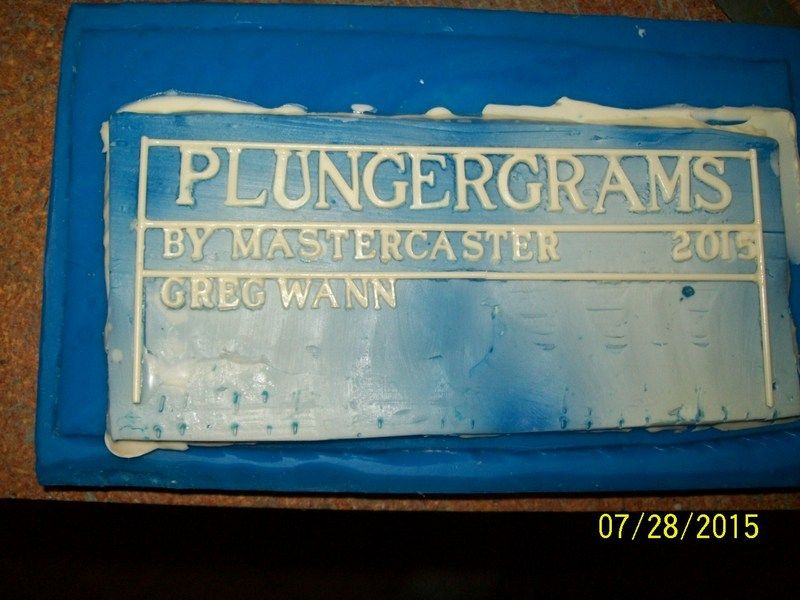

I had hoped for it to be more even but it ain't bad. removing the silicone from the back of the letters was tedious work and I only broke a couple of letters loose while the removal was taking place so that went better than expected. This is one of the reasons I use the Mold Star 30 and not the 15 because it is firmer than the 15. 15 is green and 30 is blue.  Here is one in the hardcast resin. |

|

|

|

Post by Mastercaster on Jul 28, 2015 19:54:49 GMT -8

Here is a test sample of some SMOOTH - ON Clear Flex 50. I mixed two pennies worth of one side to one pennies worth of the other side. I added enough white dye first to make it white and then a small drop of red and blue. I gave it a slight quick stir to get this effect and poured it into another cup. It has a 25 minute pot life and a 16 hour cure time. I want to make my big plungergrams sign look like this since it is made in the good ol USA. Then the small ones will be individual colors of red, white and blue. |

|

|

|

Post by Mastercaster on Jul 29, 2015 19:42:27 GMT -8

Here is the first try with the big sign. The surface is still sticky. I did some reading and found that post curing the mold when using this material will be helpful. I am hoping to get 150 degrees out of my home made mold warming box that I made some time ago. I did call tech support today. They told me the thinner the part the longer it will take to cure because there is not enough mass to generate a good amount of heat. I will preheat the mold before pouring material in it to help cure it. |

|

|

|

Post by Mastercaster on Aug 9, 2015 13:49:36 GMT -8

|

|

|

|

Post by Mastercaster on Aug 11, 2015 6:23:14 GMT -8

So far , so good. The mold is a bit too big but it turned out good. It will fit in my big horizontal pressure pot. I was hoping the silicone would come loose from the inside of master easy but that is just not happening. I should have used my mold silicone instead. |

|