|

|

Post by Mastercaster on Oct 24, 2009 10:49:01 GMT -8

Here are some flat head parts I'm doing for Chuck Granger.  Here is one boxed in. This should do two things. It will make sure no bubbles form next to the parts and it will keep the parts from getting lost in the mold by coming loose from their stands. |

|

|

|

Post by Mastercaster on Nov 8, 2009 20:19:23 GMT -8

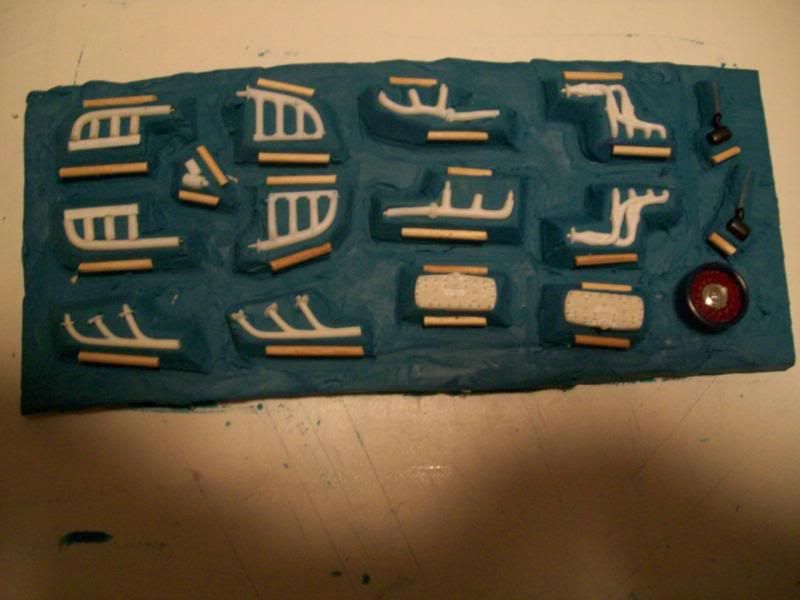

Here is a pic of the last of the flat head engine parts. I got another experimental venting idea. I cut these small round wood dowel and laid them next to the parts. My thought here is this will be another void when the mold is finished, a place where excess resin will settle making the flash even thinner. Maybe I'm just over thunking it, but another idea put to the test! |

|

|

|

Post by Mastercaster on Nov 22, 2009 19:54:18 GMT -8

Here are my findings: It is best to not pour any more resin in a cell that is necessary. I can only mix a minimum of 10 milliliters of resin at a time. there is still some waste, about a fourth gets tossed. It would still become waste but the parts might not be as nice.

|

|