|

|

Post by Mastercaster on Sept 21, 2013 9:08:31 GMT -8

Great job, Mike. Good to know the new buck is working well. Now that the procedure that you have for the glass and my tuning the body making process is better, I need to get busy on my end!

|

|

|

|

Post by Maindrian Pace on Sept 28, 2013 16:39:09 GMT -8

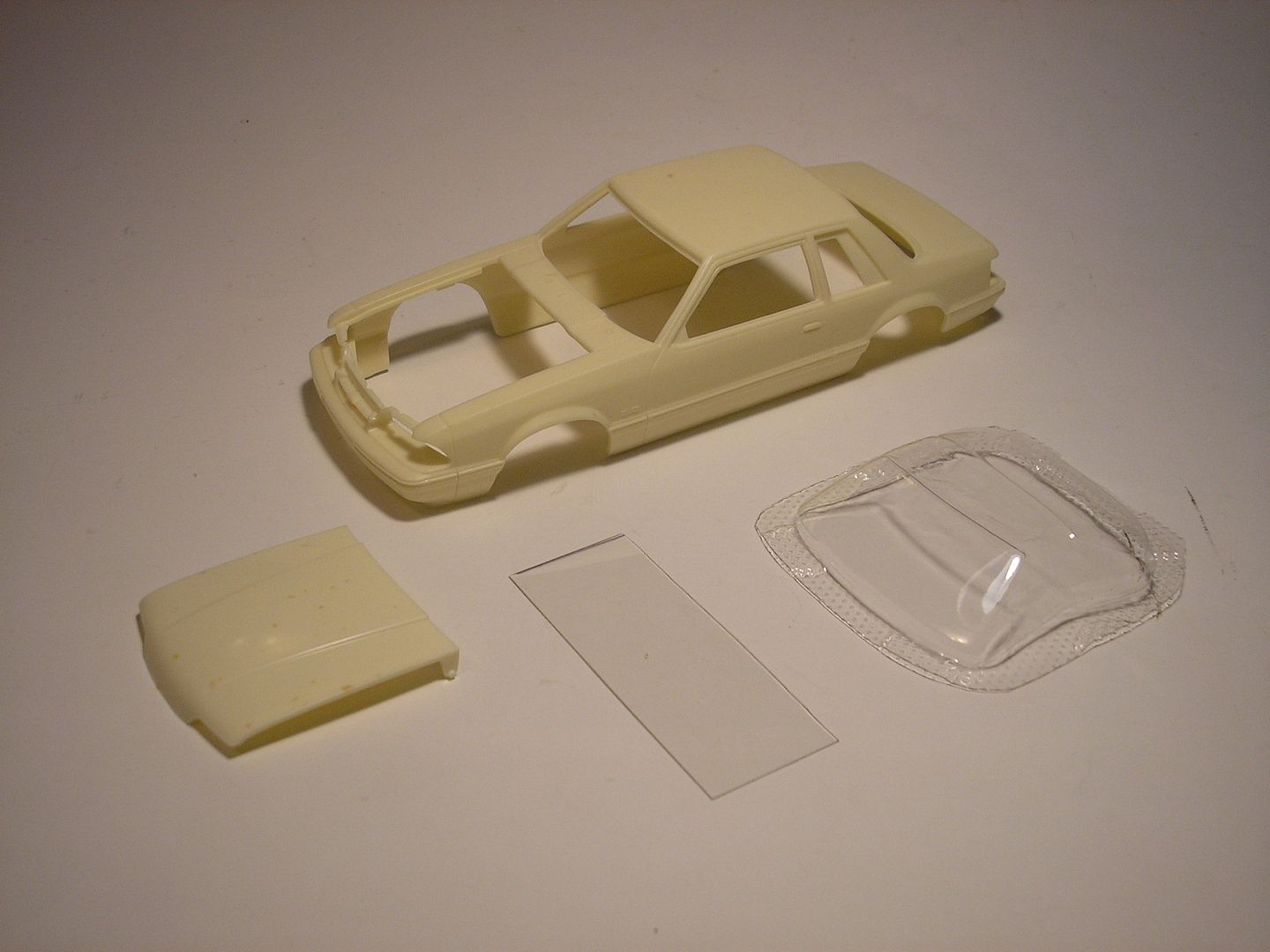

I've got all the window sets made up...

-MJS

|

|

|

|

Post by Mastercaster on Sept 28, 2013 18:24:37 GMT -8

Good to hear. I have three good bodies made. Only 15 more to go!

|

|

|

|

Post by Maindrian Pace on Sept 28, 2013 18:51:09 GMT -8

Cool! I'll get about 25 glass sets made. Got 19 so far.

-MJS

|

|

|

|

Post by Mastercaster on Sept 28, 2013 21:19:03 GMT -8

You are doing better than I am. I almost made one everyday this week. I just hope the front end of the mold holds out. All that little detail is still scary!

|

|

|

|

Post by Maindrian Pace on Oct 12, 2013 20:41:04 GMT -8

Done, contact Greg for details/ordering.  -MJS |

|

|

|

Post by Mastercaster on Dec 9, 2013 9:17:47 GMT -8

this mold has suffered some damage. A small part of silicone that forms the grille under the front bumper has pulled out. When I get the master back and the mold made production will continue. Sorry for the inconvenience.

|

|

|

|

Post by Mastercaster on Jan 3, 2014 6:26:43 GMT -8

I am making new molds of these parts. I am trying a new silicone. This is SMOOTH-ON MOLD STAR 15. It is actually cheaper than the silicone I was using. It has a much longer library life and it is not supposed to shrink. It mixes 1:1 by volume so it is much easier to use. I gave the hood a good polishing with the Koala plastic polish I found online. This polish is a good second to the Bare Metal Foil plastic polish that is no longer available. I have spent many dollars on polishes hoping it would work as well as the Bare Metal Foil polish. They just could not muster the lustre that BMFP produced. www.koalaproducts.net/beforeafterpolish.htmlwww.smooth-on.com/Silicone-Rubber-an/c2_1115_1341/index.html |

|

|

|

Post by Mastercaster on Jan 4, 2014 22:34:11 GMT -8

This mold is finished and I made a couple of hoods today. It is a good mold. I should have made it thicker on the first pour of silicone. There are a couple of places that looks like something fuzzy got on it. Probably from a cotton ball. I was hoping for a mold that could make a nice clear hood. Having spent the time to polish it seems pointless now.  |

|

|

|

Post by Maindrian Pace on Jan 5, 2014 19:09:45 GMT -8

Mmm. Shiny.

-MJS

|

|

|

|

Post by Mastercaster on Jan 5, 2014 19:28:25 GMT -8

I had been polishing the body inside and out but with this going on I'm just going to get the body clayed up and proceed as normal. I have a waiting list and I'm pretty much wasting time! This will be a better mold with new silicone. A new year and a new era for my casting experience. Well....I'm trying to be positive!

|

|

|

|

Post by Mastercaster on Jan 12, 2014 8:08:36 GMT -8

|

|

|

|

Post by Mastercaster on Jan 12, 2014 20:45:40 GMT -8

|

|

|

|

Post by Maindrian Pace on Jan 13, 2014 20:08:28 GMT -8

[Monty Burns] Excellent.[/Monty Burns]

-MJS

|

|

|

|

Post by Mastercaster on Jan 16, 2014 11:53:44 GMT -8

This mold not very good. I put the freshly mixed silicone in my vacuum chamber and still this ugly blob of resin formed on the front of the body. This means that an air bubble formed in this area and did not escape before the silicone cured.  I took my exacto knife and attempted to cut out the offending area. I am hoping that I can repair the mold like I had done with the Mercedes Ren race car transporter. putting the master back in the mold with all of this fine detail might become a problem. The body did survive the removal process.If this works then I might try to repair the first mold. |

|