|

|

Post by Mastercaster on Apr 25, 2010 13:52:03 GMT -8

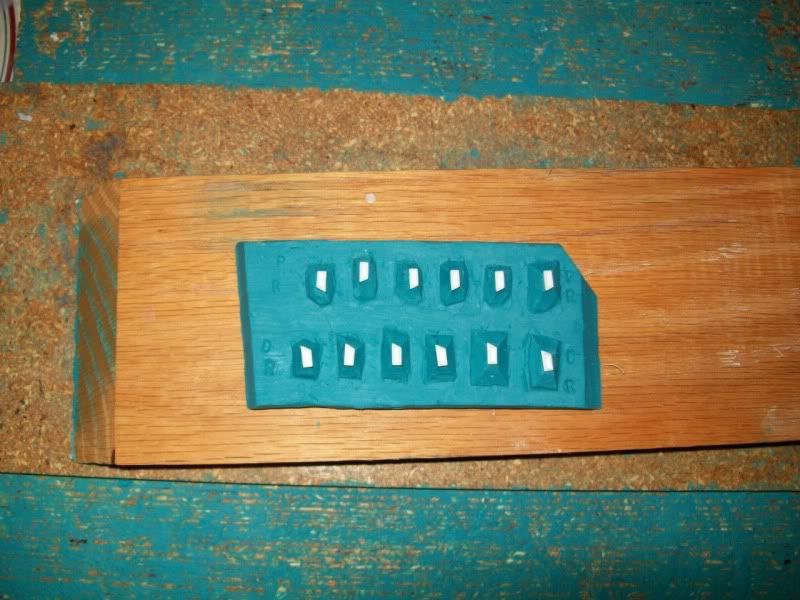

I painstakingly cut out the marker lights from the flip nose parts that I had mastered and made molds of to see if I could make them in colors for the body. I took a fresh body and removed the interior portion of the marker light and the trim chrome from the surface too. Then I will polish around the openings to remove all scratches from the body. Notice that I cut a corner off to key the mold. This is a small mold, just 88 grams so far. I just hope some how that none of the marker lights come off and float into the silicone and I have to start over. This clay is pretty sticky so I hope it goes well. Also, I took a letter stamp and marked the proper position of the lights on the body. |

|

|

|

Post by Mastercaster on Apr 28, 2010 10:16:25 GMT -8

Here is a passenger rear marker light that I put BMF on and installed in it's place. I back lit it with a small light on the top pic. |

|

|

|

Post by Danno on Apr 28, 2010 15:17:31 GMT -8

Those look great, Greg!!

|

|

|

|

Post by Mastercaster on Apr 28, 2010 15:40:09 GMT -8

Thanks. Now I'm making several copies to have masters to make another mold that will make 6 copies at one time. It's a sort of labor of love!

|

|

|

|

Post by Mastercaster on Apr 29, 2010 7:54:58 GMT -8

Here are six rear marker lights for each side of the car. It only takes a good size drop of resin to make one. Claying these little parts up takes a bit of work too. |

|

|

|

Post by darkrapid on Apr 29, 2010 21:40:13 GMT -8

That is really cool. Nice idea.

So you got your room back in order and are back to casting? Your Firebird body is almost ready. I just have a few more sections to touch up. It will be ready by this next meeting.

|

|

|

|

Post by Mastercaster on Apr 30, 2010 5:58:22 GMT -8

Thanks Raoul,

I appreciate your helping me with this project. I made molds of the seats and steering wheel. Hopefully I will remember to bring them to the meeting too. I have another project to show you that you might be able to help with. I will post pics.

|

|

|

|

Post by Mastercaster on Apr 30, 2010 12:17:53 GMT -8

Well.....Here is the first batch of marker lights out of the bigger mold. I pulled the first two out and realized I had screwed it up. One red marker light does not belong in that group. I can't believe I missed it completely! After all the checking, labeling, testing, grouping and bagging and then test fitting again, I still screwed it up!! This really does suck!  |

|

|

|

Post by Mastercaster on Jul 3, 2011 19:36:43 GMT -8

Here is a third attempt at a good mold for my GSX flip nose creation. I cut these pieces of acrylic so that it would fit in my vacuum chamber. I am trying a new way of making a mold while using the ground up silicone. I'm thinking that by using the ground up silicone it might cause problems of trapping air in the parts detail. This way I am hoping that by directly inserting the mold box in the vacuum chamber it will help. My first two molds make bodies with deformities I do not want. This time I left the firewall in. |

|

|

|

Post by darkrapid on Jul 3, 2011 20:59:23 GMT -8

That is clever! I hope it works out for you!!

|

|

|

|

Post by davewilly on Jul 6, 2011 9:20:43 GMT -8

Hey Greg it all looks pretty cool. I am glad you share all your casting stuff with us its pretty interesting to follow along with and also learn that its not all that easy to make a quailty product like you do. Keep up the great work!

|

|

|

|

Post by Mastercaster on Jul 6, 2011 12:27:00 GMT -8

Thanks Dave, My wife says all I do is play! It just looks that way. I used to underestimate my talent until Bob Peoples hooked me up with Mike Hanson who was just blown away with my work. He has given me a couple of parts to make molds of. Posting here is a sneaky way of having an online catalog.

|

|

|

|

Post by davewilly on Jul 6, 2011 13:35:33 GMT -8

Well I could add a Resin parts thread and you could list them all in there and use the thread as a online catalog so to speak

|

|

|

|

Post by Mastercaster on Jul 16, 2011 23:00:38 GMT -8

Thanks, I sent you a PM

|

|

|

|

Post by Mastercaster on Jan 7, 2018 20:49:20 GMT -8

It has been some time now. Have some interest in these. Needed a new mold. I hand fit each one in the master from years ago. It will make 15 of each one this time. These are tiny and fiddly, much like handling a photo etch part. If you drop it, good luck finding it. resinmodelcasting.proboards.com/holygrailresins@gmail.com |

|